Guide to Warehouse Shelving for Optimal Storage

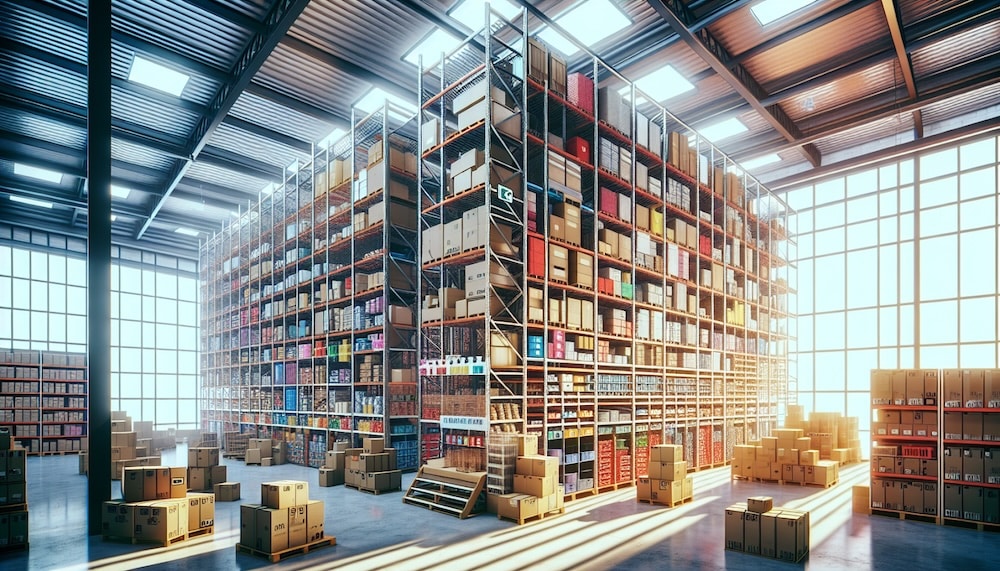

Efficient warehouse shelving maximizes space and streamlines operations. This guide explores different shelving types, space optimization techniques, and essential safety practices. Discover practical solutions to improve your warehouse shelving with the best shelves for your needs.

Key Takeaways

- Understanding your storage needs is crucial for optimizing warehouse space, which involves analyzing inventory and planning for future demands.

- Different types of shelving and racking systems (like metal shelving, wire decking, and pallet racks) cater to various storage requirements, enhancing efficiency and safety.

- Regular maintenance and safety compliance are essential to prolonging the lifespan of warehouse storage solutions while ensuring a safe working environment.

Understanding Warehouse Shelving Needs

The journey to an optimized warehouse begins with a thorough understanding of your storage needs. This involves analyzing your current inventory and anticipating future demands to create a system that can adapt and grow with your business. Analyzing inventory helps identify suitable storage solutions for different items, ensuring efficient and safe storage.

Categorizing inventory types, like raw materials and finished goods, determines appropriate storage methods. Similarly, assessing inventory volume and size helps choose the right storage configurations, like shelving or racking.

Understanding item access frequency helps you optimize storage locations, which enhances overall efficiency. Planning for seasonal variations and future demands keeps your storage system efficient, thereby helping you maintain customer satisfaction.

Types of Warehouse Shelving Units

Warehouse shelving units come in a variety of materials and designs to meet different storage needs. From durable metal shelving to versatile wire decking and robust heavy-duty options, each type offers unique advantages.

Keep in mind that the right type depends on specific storage requirements and operational environment.

Metal Shelving

Metal shelving is a popular choice in warehouses due to its durability and strength. These shelving units are resilient against impacts and vibrations, making them ideal for busy industrial environments. Metal shelving offers effective storage and withstands heavy use, making it reliable for various materials and products.

Wire Decking

Wire decking improves airflow and visibility, reducing dust accumulation and maintaining product integrity. Wire decking is essential in shelving systems, providing support and safety while improving cleanliness and item condition.

Heavy Duty Shelving

For warehouses storing bulky and heavy items, heavy-duty shelving is the go-to choice. Constructed from high-gauge steel, these industrial shelving units and warehouse storage racks are designed to handle substantial weights safely.

Heavy-duty shelving meets demanding storage requirements without compromising safety.

Pallet Racking Systems

Pallet racking systems are critical for maximizing storage space and organizing inventory efficiently. Choosing the right pallet rack type based on needs and budget achieves optimal storage solutions.

Selective Pallet Racks

Selective pallet racks, the most widely used type, provide direct access to each pallet without needing to move others. This type of racking is easy to install and can be integrated with various shelving systems, enhancing storage efficiency.

Wire decking improves airflow and visibility, suitable for storing perishable goods or items needing ventilation.

Drive-In Pallet Racks

Drive-in pallet racks allow forklifts to enter the rack structure for high-density storage, accessing pallets stored deep within. This system is ideal for operations where high-density storage is prioritized over selectivity, making it a perfect fit for warehouses with large quantities of uniform products.

Push Back Pallet Racks

Push back pallet racks use carts that slide back, enabling multiple pallets to be stored in a single lane, optimizing space. This system enables storage on both sides of an aisle, significantly enhancing storage density.

Combining static and dynamic racks in push back systems enhances flexibility, accommodating both frequently used and less accessed items.

Optimizing Storage Space with Warehouse Shelving

Various shelving units cater to different storage needs and significantly optimize space usage in warehouses. Utilizing vertical space, considering aisle widths, and organizing inventory effectively are key strategies to maximize storage efficiency and improve warehouse operations.

Vertical Space Utilization

Vertical storage solutions greatly enhance a warehouse’s capacity and operational efficiency. Using tall shelving units allows warehouses to take advantage of high ceilings, increasing storage capacity without expanding the floor area. Drive-in pallet racks are an example of high-density storage that utilizes vertical space efficiently.

Aisle Width Considerations

Aisle width directly influences storage efficiency and forklift accessibility. While narrower aisles can increase storage density, they may limit forklift maneuverability, affecting workflow and safety. Balancing aisle width ensures maximum storage capacity and easy navigation.

Organizing Inventory

Effective inventory organization enhances accessibility and streamlines warehouse workflow. Selective pallet racks, adjustable shelves, and logical categorization of inventory can significantly improve both accessibility and workflow efficiency. Grouping and labeling similar items reduces retrieval time, increasing overall efficiency. Or arrange inventory so that your best-selling products are stored closest to the loading docks for faster fulfillment.

Adjustable and Modular Shelving

For warehouses that experience changing storage needs, adjustable shelves and modular shelving systems provide flexibility to accommodate varying product sizes and configurations. This adaptability ensures that your warehouse shelving can respond to fluctuating inventory and seasonal demands.

Implementing a Shelving Rotation Plan

As inventory turns over, having a system in place to reorganize and rotate stock helps maintain optimal storage efficiency and avoid bottlenecks. This practice keeps frequently accessed items easily reachable and ensures that your system remains efficient over time.

By combining these strategies, you can maximize your warehouse’s space and optimize operations.

Related: Warehouse Racking Layout: Top Strategies for an Efficient Facility

Fire Safety and OSHA Compliance for Warehouse Shelving

Fire safety and compliance as well as following OSHA guidelines are paramount in warehouse operations. Sprinkler systems must adhere to NFPA guidelines, ensuring clearances between sprinkler heads and racks for effective fire suppression. Regular inspections help detect damage early, preventing costly repairs and ensuring safety.

Training staff on proper loading techniques and safety compliance is crucial for maintaining a safe environment.

Choosing Quality Warehouse Equipment

Choosing quality warehouse equipment ensures long-term efficiency and safety. Evaluating steel type, with lower impurity ratios indicating higher quality, is important. Durability of rack components and proper installation are vital to maintaining load-bearing capacity over time.

Coating techniques like electrostatic painting and galvanizing enhance the longevity of steel racks by providing corrosion resistance. Ensuring compatibility with specific warehouse needs, like scale and type of goods managed, is also key.

Customizable Shelving Solutions

Customizable shelving solutions provide flexibility and adaptability for various storage needs. Adjustable shelves, modular shelving systems, and specialized storage options enhance space optimization and responsiveness to changing inventory demands.

Adjustable Shelves

Adjustable shelves in warehouses allow customization for varying product sizes. These metal shelving units can accommodate different heights and types of inventory, making them versatile and practical.

Modular Shelving Systems

Modular shelving systems ensure flexibility to meet changing inventory needs. These systems can be easily reconfigured and adapted, offering versatile storage solutions tailored to specific requirements.

Modular shelving enhances space optimization and responsiveness to storage demands.

Specialized Storage Options

Specialized shelving addresses the storage needs of unique items like tires and lumber. Tire racks and storage racks accommodate the weight and shape of tires, maximizing vertical storage and ensuring easy accessibility in the store.

Lumber storage systems use horizontal shelving to support long boards securely, minimizing damage and enhancing access. These solutions improve storage efficiency and organization for unique product types.

Proper Maintenance of Warehouse Racks and Shelving

Regular maintenance of warehouse racks and shelving ensures longevity and safety. Regular inspections identify and address signs of wear or safety issues, preventing costly repairs and prolonging storage system lifespan.

Professional inspections can uncover hidden damage, and documenting inspections and repairs tracks maintenance history and identifies recurring issues. Rack protection products minimize damage from forklifts and reduce maintenance costs.

Cost-Effective Shelving Solutions

Cost-effective shelving solutions help businesses maximize storage without overspending. Wire shelving, for instance, balances affordability with the ability to withstand heavy loads and accommodate different inventory sizes.

Incorporating budget-friendly options ensures efficient and practical storage solutions for warehouses.

How to Assemble Warehouse Shelving Units

Assembling warehouse shelving units requires careful attention to ensure stability and safety. Start by gathering essential tools like a rubber mallet, wrenches, and a level.

For rivet system shelving, construct the base by inserting rivets into the uprights, securing cross beams, and installing shelves.

When assembling pallet racks, position the uprights, insert the beams at the desired height, and add wire decking.

For bulk storage racks, insert beams and decking securely while distributing weight evenly.

Always perform a final safety check to ensure all components are securely fastened and shelves are level.

Summary

Efficient warehouse shelving is key to maximizing space and improving workflow. This guide explores various shelving types, from metal shelving to pallet racking systems, along with practical tips on optimizing storage space, vertical utilization, and ensuring safety compliance. By understanding your inventory needs and choosing the right shelving system, you can enhance operational efficiency and create a safer, more organized warehouse environment.

Looking to improve your warehouse operations and maximize efficiency? Cadre Technologies’ warehouse management software integrates seamlessly with any shelving system, providing real-time tracking, inventory management, and workflow optimization. Contact us today to learn how our solutions can help you streamline your operations and enhance productivity!

Frequently Asked Questions

What factors should I consider when choosing warehouse shelving?

When choosing warehouse shelving, you should think about the volume and size of your inventory, how often you need to access it, and any future changes in demand. This will help you create a flexible system that meets your needs.

What are the benefits of metal shelving in a warehouse?

Metal shelving is incredibly durable and can handle heavy use, making it perfect for storing various materials in a warehouse. It’s a reliable choice that can withstand impacts and vibrations, ensuring your items are safe and secure.

How can I optimize vertical space in my warehouse?

To optimize vertical space in your warehouse, invest in tall shelving units and high-density storage solutions like drive-in pallet racks. This will help you make the most of your high ceilings and maximize storage capacity efficiently.

Why is regular maintenance of warehouse shelving important?

Regular maintenance of warehouse shelving is crucial because it helps spot wear and safety issues early, preventing costly repairs and ensuring everything runs smoothly. Keeping your shelving in top shape not only extends its life but also boosts safety and efficiency in your operations.

What are some cost-effective shelving solutions?

Wire shelving is a great cost-effective choice since it’s affordable, sturdy, and versatile enough to handle various inventory sizes. Another option is boltless shelving, which is easy to assemble and adjust, providing flexibility for different storage needs. Plastic shelving is also a budget-friendly solution for lighter-weight items, offering durability and resistance to corrosion without the higher cost of metal shelving.